WE PROVIDE WORLD-CLASS END-TO-END LIFECYCLE SAP IBP SERVICES TO DELIVER THE EXPECTED VALUE.

Whether you are starting the journey, looking to improve an existing implementation or needing post-implementation support that continues to improve results, we are here to help.

STARTING THE JOURNEY: DOING IT RIGHT THE FIRST TIME

Other systems integrators “turn the dials” – they have people that can configure the modules but lack the fundamental understanding of supply chain concepts and processes. This means that their implementations take longer, cost more and don’t deliver the value.

The RENI approach is better, faster and cheaper – better because it delivers the expected value, and faster and cheaper because of the configurable best-practices templates that meet the business and user needs effectively.

The RENI approach is built on combining industry expertise, process knowledge, and technical skills to implement the solution that delivers value by

- Tuning it to the business priorities

- Establishing an exception-based process

- Configuring the modules for effectiveness, and

- Enabling users to perform their tasks easily

IMPROVING AN EXISTING IMPLMENTATION: EXTRACTING THE VALUE

Companies go into SAP IBP implementations with the expectation of significantly increasing forecast accuracy, improving delivery performance, reducing inventory and E&O levels, and reducing supply chain operating costs. But, while there may be some marginal improvements to these targets, the results are well below expectations and not sustained for very long.

Common outcomes are:

- After 3 months, the anticipated results have not been achieved – improvements in forecast accuracy and inventory turns have not been achieved, costs have not changed much, simultaneous improvement in delivery performance and inventory reduction are not happening. Expediting and inside lead time focus is still business as usual.

- After 9-12 months, users are not really using the system, they have gone back to Excel and old practices of planning – silo’ed demand and supply plans, no real S&OP consensus, not much of scenario analysis to support real INTEGRATED BUSINESS PLANNING

The problem is not with SAP IBP. The solution has many capabilities that can drive real value. The problem is with the way the solution is designed and implemented. And by that we mean not just how the tool is configured, but also how it is built around a process, how the capabilities and workflows are aligned to the work people do to provide the right inputs and do the right tasks, and finally what expectations of value should be targeted and are achievable.

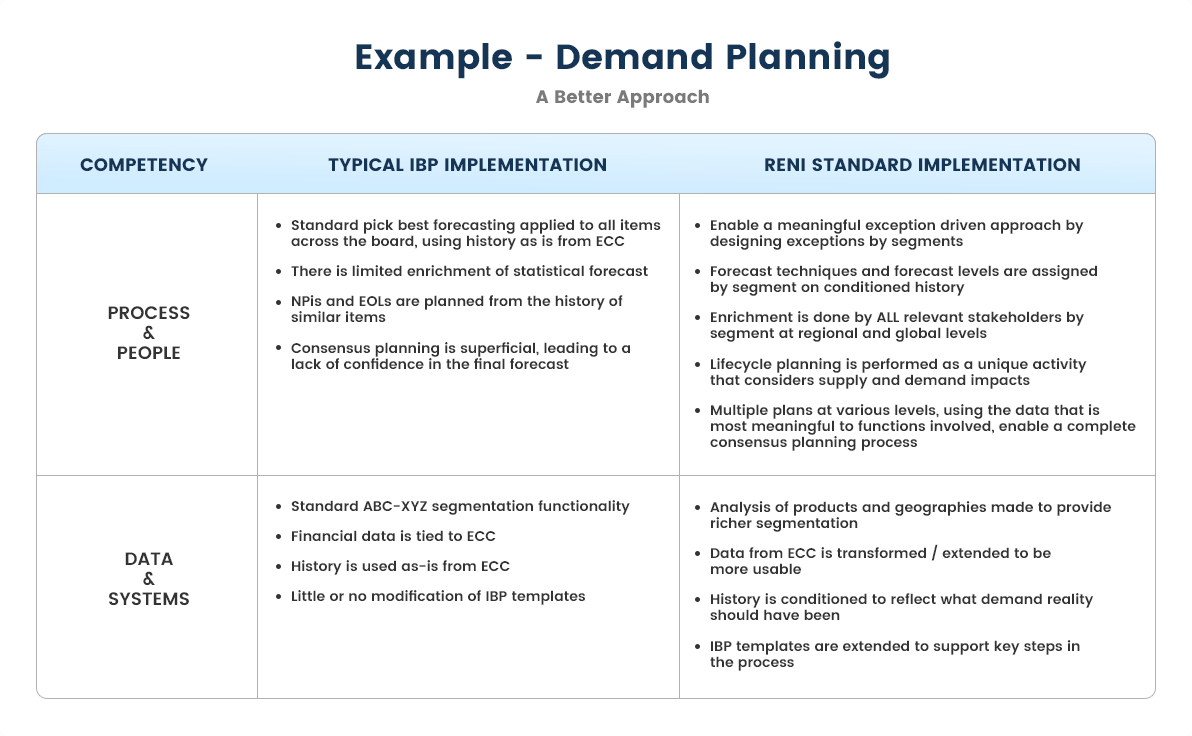

Common implementation shortcomings are:

-

- Model (structure definitions) and planning parameters are not setup right

- Demand planning hierarchies are not defined with sufficient flexibility to meet the needs of the process (local and global) and users, do not fit well with many key activities

- Forecasting algorithms and approaches are not well defined – what to forecast (which item-location segments, what demand streams), how to forecast (what techniques, at what level, for what lifecycle behavior), and where to focus (what data/intelligence to capture, how to disaggregate)

- Inventory planning is either too simple or too complex – no proper design of inventory positioning, postponement, cycle stock and safety stock parameters – or use of complex multi-echelon when not needed or not setup with the right cost tradeoff parameters

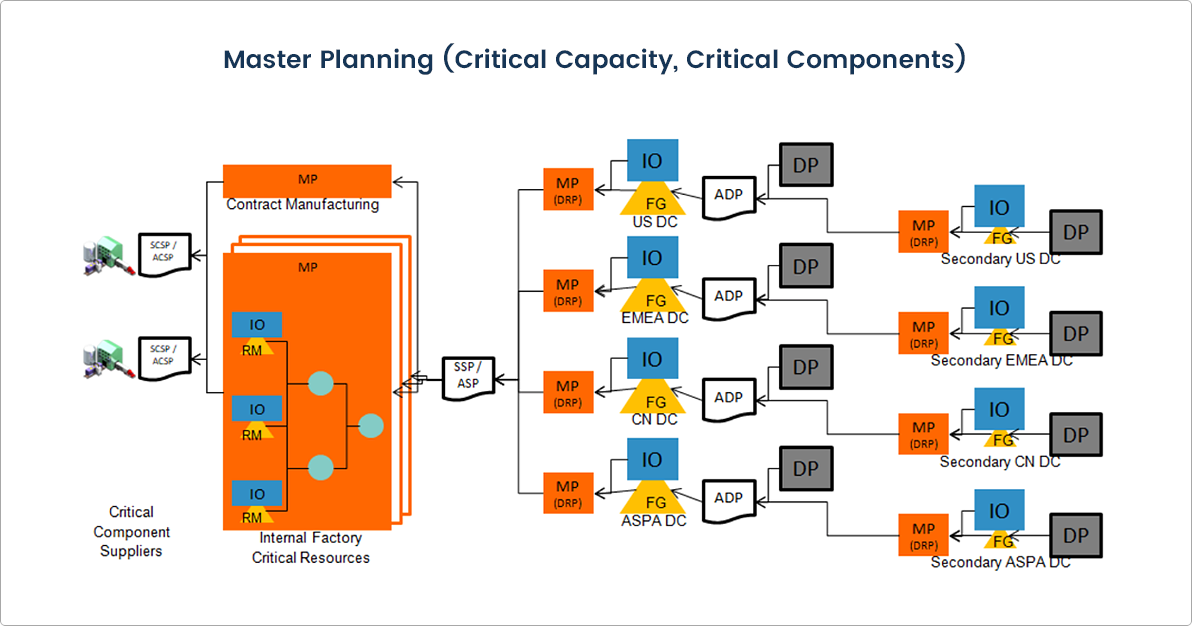

- Supply planning model not designed with the right level of detail of critical components and capacities

- Model (structure definitions) and planning parameters are not setup right

-

- Process is not setup right

- Demand planning process does not ensure the right steps are done in the right sequence to create a statistical baseline; enrich with field & marketing intelligence from all the key participants; and drive alignment with corporate goals and gain consensus, at multiple levels (of management, by geo and markets, etc.)

- Inventory and supply processes are blackboxed, which caused a loss of confidence

- S&OP process is not designed to address and resolve exception-based demand-supply mismatches and scenarios within and outside leadtime

- Process is not setup right

-

- People focus is not setup right

- Demand planning process and tools were not setup to allow people to work more effectively and efficiently (to get the right intelligence on the right products from the right people at the right time)

- Supply planners are not fully educated on how the inventory and supply optimization models work for them to develop and analyze various scenarios

- Templates are not extended or tailored to specific activities within the various processes

- Exception criteria for processes are not well defined, creating, at best, frustration to identify key issues and research causes; and, at worst, confusion as to where to spend time

- People focus is not setup right

-

- Expectations were not setup right

- There was limited or no understanding of how much forecasting accuracy, inventory reduction or cost reduction could be achieved

- Expectations were not setup right

We believe that we have unique skills, knowledge and experience to make targeted improvements to make the SAP IBP implementation deliver the value it can and should. We have built solution templates using our strong domain knowledge in various industries, world-leading supply chain planning expertise, and deep technology and analytical skills. These templates and analysis tools allow us to quickly diagnose shortcomings in the current implementation, recommend changes that will deliver the most value, and implement those changes quickly and with a high ROI.

What we do to make it right/better:

- Design right

- Utilize best practice processes, the key to ensure alignment and consensus throughout

- Leverage analytics where is can add value in the design

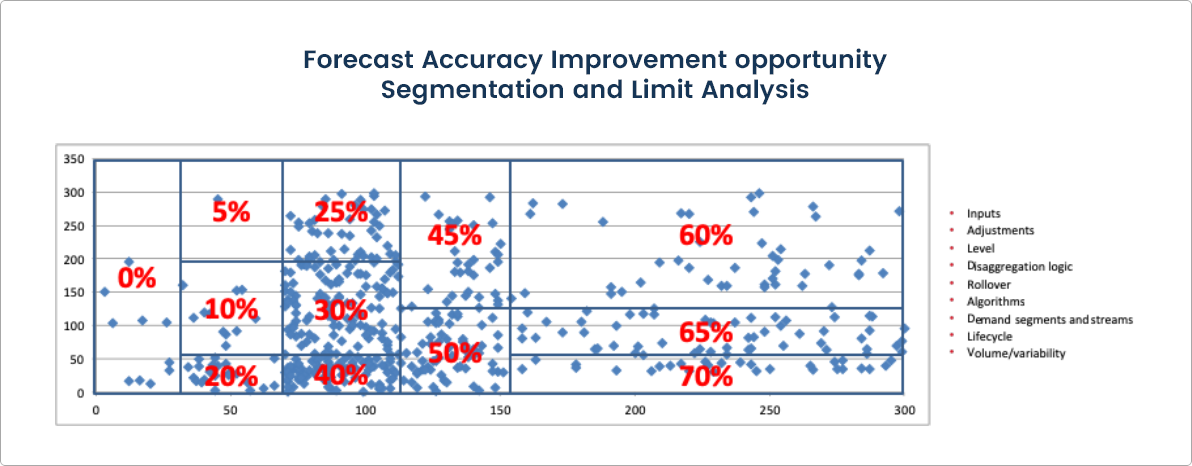

- Define segmentation beyond ABC-XYZ, the key to setting up the model correctly and focusing people on what is important

What we do to make it right/better:

- Build right

- Perform Supply Chain Limit Analysis™, deep data analysis to evaluate what improvements can be achieved with the business structure and constraints

- Tailor and extend the standard solution and process templates to drive effective adoption and use and drive value attainment

- Ensure the relevant data and exception-based reports available to each activity, in the form that they are best used to drive input and decisions

- Ensure adoption

- Design and build processes that are exception driven, allowing the participants to focus on the truly important

- Ensure plans are expressed in the terms (the measures and the time horizons), using the relevant data that each user understands

- Provide plan(s) performance feedback, from multiple perspectives, at multiple levels

- Build ownership & consensus

- Empower each participant to understand their plans and its results; to identify key exceptions; support the research into causes, and capture information to support consensus discursions

- Enable the construction of scenarios that can support consensus discussions

- Close the loop

- Design and build processes and templates that help evaluate results, comparing them to historical performances, but also against corporate plans (sales goals, AOP, geo plans, etc.), using the measures that are important to each functional group

- Identify areas of the model and the planning parameters that should be considered for “immediate” tuning

- Review the model assumptions, segmentations, exception criteria, etc., on a periodic (quarterly or semi-annual) basis

An effective implementation of SAP IBP capabilities goes beyond consultants from other companies that are only capable of turning the dials to configure the application. It requires RENI’s professional-grade consultants with a unique blend of industry domain knowledge, world-class supply chain planning expertise, deep analytical skills and strong SAP IBP technical skills. We can take an existing implementation and make it deliver the expected value through targeted changes that combine technology, process and change management. And we can deliver it quickly and with a very high return on investment.

Whether you have completed one or are in the middle of an implementation, contact us to schedule a Supply Chain Planning Rapid Diagnostic to get the journey started towards real value generation.

CONTINUOUS IMPROVEMENT: FIX AND ENHANCE

Post-implementation support is all the same, right? Wrong!

Other SI’s put junior offshore consultants to provide support for bug fixes – order takers that jump in when there is a problem, but otherwise are twiddling their thumbs waiting for something to break.

Our approach is different. If we are taking over support for an implementation done by another SI, we use our Supply Chain Planning Rapid Diagnostic to transfer knowledge quickly and efficiently. This also enables us to find opportunities for improvement from the start. While we prioritize support activities, our offshore consultants are trained to recommend and implement improvements when they are not busy. And, we bring our onshore leaders to provide best practice knowledge and oversight to both the support and enhancement activities. We are constantly monitoring new releases from SAP to determine which enhancements will provide quick value to the business. We proactively recommend these changes to you and, once approved, deliver the capabilities and ensure user adoption.

So, in a short period of time, we are making the system better and continuing to deliver incremental value.